So I'm attempting to install a 12fpe kit into my TX200 but have run into an issue. With one spacer installed, I am getting 10.5fpe with FTT 8.64gr and closer to 11 with AA 10.6gr pellets. When I add another spacer to bring it up some, the piston rod won't latch on the sear. Everything is bottoming out on the trigger assembly so its safe to assume the added spacers are making the piston rod just a bit to short to work properly. Any advice or am I possibly (probably) doing something wrong?

Side notes, the original top hat has been removed and the safety wasn't engaging properly with just the single spacer either. With no spacers and the spring in the highest position in its seat, I'm getting just over 10ftlbs.

Edit: Am I supposed to unscrew the latch rod some to compensate?

Edit #2: the spring guide does not fit completely into the piston with spacers installed. Will reduce spring guide length by 0.25" (depth of spacer x2) unless someone has a better answer.

Edit #3: Issue resolved

Here is a picture of how the guide fits into the piston with no shims/spacers for preload. Perfectly flush.

With a single shim installed the gap was slight but hardly noticeable. In this picture, both shims are installed and the gap is quite noticeable.

With the stock off and cocking the action with no shims installed I noticed that I could both hear and feel the sear and safety engaging just as the piston bottomed out on the base of the guide. With the gap seen in the picture above, the piston rod wasn't able to fully engage the sear.

Solution: I measured both spacers and got a total depth of just under 0.25". Using a small tubing cutter, I cut off 5/16 of an inch from the guide to compensate for the shims it was contacting and thus preventing the piston rod to go all the way rearward into the trigger assembly.

Using a bench grinder, I then added a small taper around the end of the guide to help ease it into the piston when cocking. I finally gave it a quick polish with 180 and 800 grit sandpaper to smooth it out. It works flawlessly.

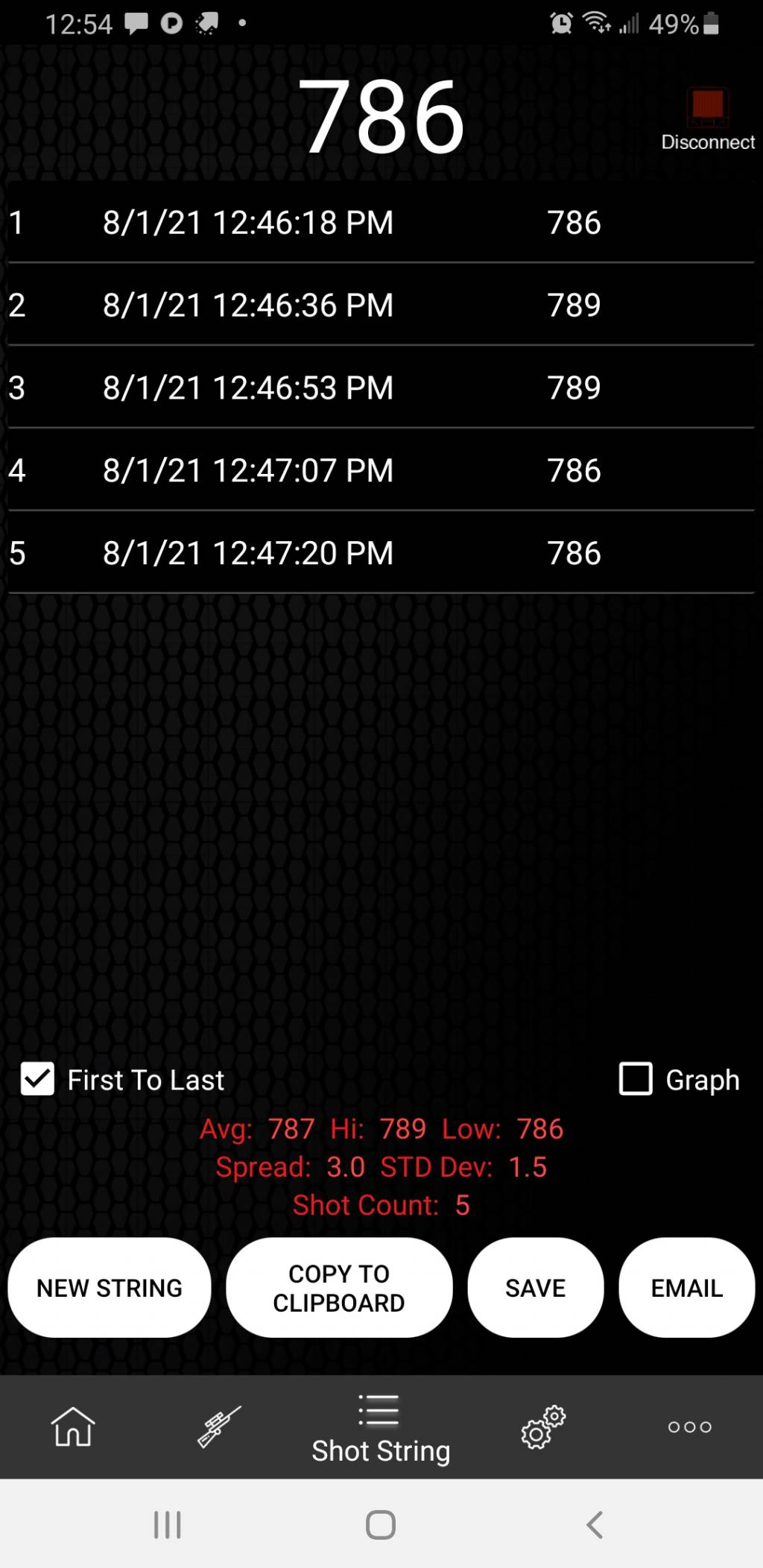

With both shims installed I threw a quick 50 shots down range to allow things to settle in after reassembly. I am now sitting at a comfortable 11.6fpe from my TX200. Now to just break it all in some and recheck my numbers in a tin or two.

5 shots, 50yds, JSB 8.44gr

Side notes, the original top hat has been removed and the safety wasn't engaging properly with just the single spacer either. With no spacers and the spring in the highest position in its seat, I'm getting just over 10ftlbs.

Edit #2: the spring guide does not fit completely into the piston with spacers installed. Will reduce spring guide length by 0.25" (depth of spacer x2) unless someone has a better answer.

Edit #3: Issue resolved

Here is a picture of how the guide fits into the piston with no shims/spacers for preload. Perfectly flush.

With a single shim installed the gap was slight but hardly noticeable. In this picture, both shims are installed and the gap is quite noticeable.

With the stock off and cocking the action with no shims installed I noticed that I could both hear and feel the sear and safety engaging just as the piston bottomed out on the base of the guide. With the gap seen in the picture above, the piston rod wasn't able to fully engage the sear.

Solution: I measured both spacers and got a total depth of just under 0.25". Using a small tubing cutter, I cut off 5/16 of an inch from the guide to compensate for the shims it was contacting and thus preventing the piston rod to go all the way rearward into the trigger assembly.

Using a bench grinder, I then added a small taper around the end of the guide to help ease it into the piston when cocking. I finally gave it a quick polish with 180 and 800 grit sandpaper to smooth it out. It works flawlessly.

With both shims installed I threw a quick 50 shots down range to allow things to settle in after reassembly. I am now sitting at a comfortable 11.6fpe from my TX200. Now to just break it all in some and recheck my numbers in a tin or two.

5 shots, 50yds, JSB 8.44gr