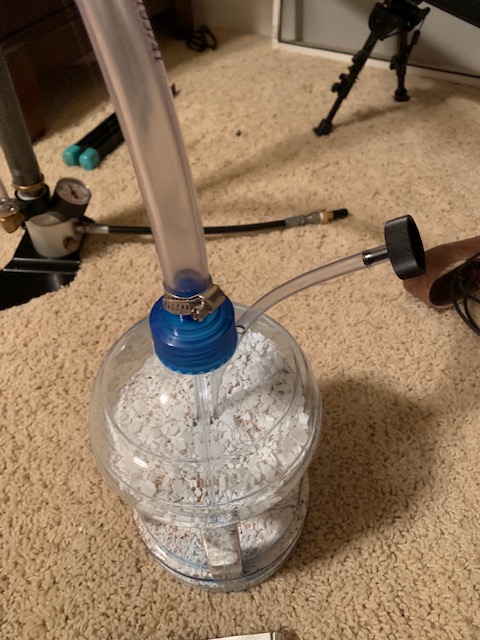

Certainly. When pumping the thumb screw on the dip tube is removed, if I don't do this, it creates a vacuum. The dip tube is sealed inside the bottle with a drilled hole the same size as the input hole into the Hill MK3. I am only using the pump connection from the Hill moisture kit. When pumping during the upstroke there is a clearly audible 'hiss' as air is drawn in via the dip tube. This helps me better "time" my downstroke pump to ensure maximum intake -- the hissing stops when the pump is full of equalized pressure air awaiting the pump down stroke.

Quick disconnect fitting, the vinyl tubing is placed around the blue top, there is a nodule that sticks out that originally held a plastic drinking nipple. The fitting on the Hill MK3 is covered when not in use to prevent debris ingress.

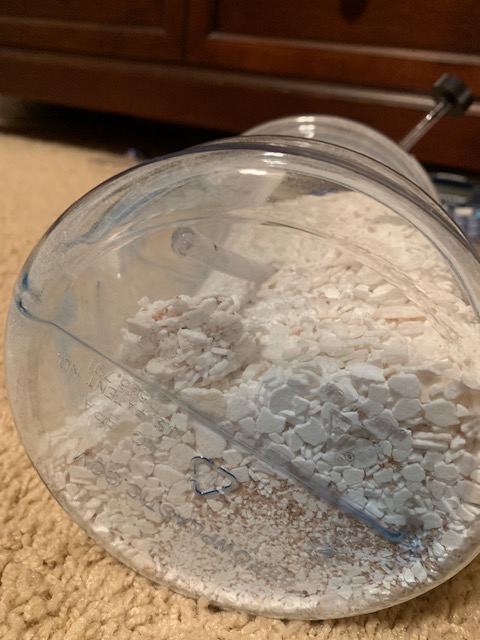

Initial construction of the bottle prior to filling with damprid ($10 USD 'bucket' in the RV section at major retail stores). The hole drilled into the bottle to accommodate the dip tube is smaller in diameter than the flexible tubing allowing for a seal to be formed. At the bottom of the dip tube that is sealed off at the very bottom there is a hole drilled the same diameter as the hole on the air intake for the Hill MK3.

The dip-tube thumb screw to seal the system off hermetically to keep the calcium chloride from processing moisture in the ambient air when not pumping is shown below. I had this part lying around but anything to block the dip tube would work fine.

The salt-moisture ball I was speaking to earlier. This shows a mild amount of moisture has been collected by the calcium chloride salt. If you've never used "damprid" before it turns to a salt-water solution when no longer capable of adsorbing water. By having the dip tube below the surface of any potential water collection I've maximized the filter medium exposed since air is drawn through the dip tube to the bottom, through the filter medium, and out from the top into the hand pump. Additionally, if any salt-water solution were to exist in the bottom it would not be drawn into the pump and would also be clearly visible. In the picture below the black/brown circle on the dip tube is actually the drilled hole the same diameter as the air intake hole on the MK3. The goal here was to ensure a reasonable air flow rate into the filter medium to maximize moisture removal. The end of the dip tube, aside from the drilled hole, is sealed.

Finally, this is the felt pad I was speaking to, I have little concern of salt dust or debris making it past this. The wide tube into the pump allows for maximum air flow without creating a significant air disturbance or stirring up any dust to be collected by the felt filter. The felt filter is about 1/8" to 1/4" thick. The discolored ring on the felt filter is not debris or salt dust, it's where the edges of the felt soaked up the Elmers glue used to glue the filter in place.

Total cost of the entire setup was less than $15 USD. The filter medium should last for years and would run about $10 from any local large retailer to replace. The goal of the project was to have clear visual indication when to change, create something that was easily portable and able to be disconnected quickly, be hermetically sealed when not in use to avoid unnecessarily removing moisture from the ambient air when not pumping, and to increase the amount of moisture removing medium significantly.

After every pumping there are no signs of moisture around the relief valve, on my fingers, or anywhere. The air expressed from the relief valve at 200-210 bar shows no signs of any moisture collection.

Hope this helped,

LMNOP