You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Picking a compressor

- Thread starter Hw9720

- Start date

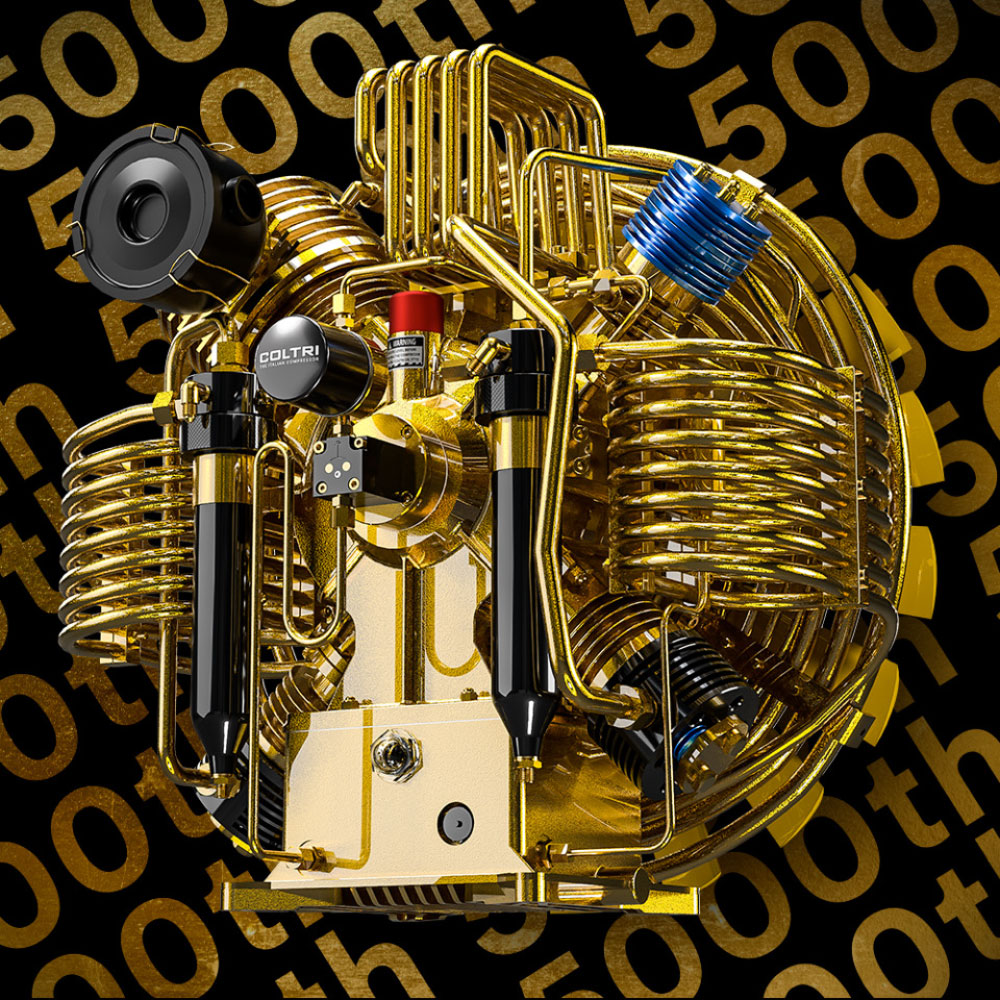

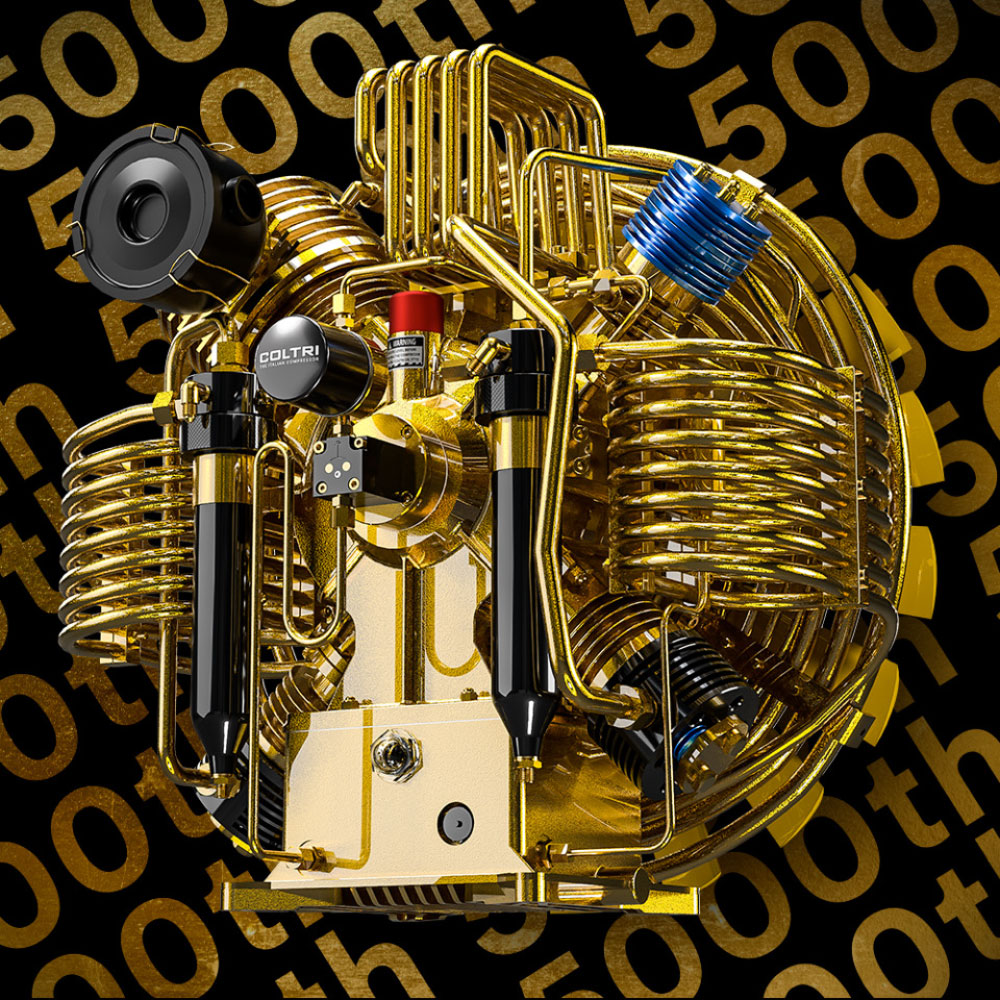

That seems slightly less portable……..This was my friend Joe's "pick".

Delivered today. Glad he's my friend

Patrick

View attachment 314293

Upvote 0

True words you say.That seems slightly less portable……..

Possible solution.

A 97CF SCBA.

P

Upvote 0

Patrick, what was Joe’s reasons for picking up a horizontal unit? I’m just curious as most Alkin buyers get the vertical model. There is no price difference between the two.This was my friend Joe's "pick".

Delivered today. Glad he's my friend

Patrick

View attachment 314293

Upvote 0

Now thats a compressor.

I would call it 2 man portable, maybe 1 if you are young,,,,,, as i am no longer young would have to devise some easy way if i was to move something like that on a regular basis.

BTW did anyone see Coltri made a battery compressor,,,,,, that be a proper big compressor, must be SOB heavy stacked with 740 Wh battery too.

I would call it 2 man portable, maybe 1 if you are young,,,,,, as i am no longer young would have to devise some easy way if i was to move something like that on a regular basis.

BTW did anyone see Coltri made a battery compressor,,,,,, that be a proper big compressor, must be SOB heavy stacked with 740 Wh battery too.

Last edited:

Upvote 0

@Peashooter - That is an impressive compressor. Would not want guess how much that one goes for.

I have the Omega Trail Charger with about 10 hours on the it. Works great, love the portability of it. I purchased the Omega Personal Compressor five years ago. I have over 60 hours on it and it with no issues.

I am really "pumped" at how much more available compressors have become in the last two years. Really makes it easy to get into PCP's. The DC and battery options are getting better and better. Perhaps they can focus on the noise levels next.

I have the Omega Trail Charger with about 10 hours on the it. Works great, love the portability of it. I purchased the Omega Personal Compressor five years ago. I have over 60 hours on it and it with no issues.

I am really "pumped" at how much more available compressors have become in the last two years. Really makes it easy to get into PCP's. The DC and battery options are getting better and better. Perhaps they can focus on the noise levels next.

Upvote 0

Actually it only do 80L/min where as most of the other portable Coltry are 100 L / min

I have not been able to find much info on it, or even a price, to me so far it lust look like a "look what we can do" product.

TBH i personally feel that large of a battery compressor are a bit silly, i also wonder how many fills you can do on a standard sized dive bottle, or even just a boost from say 200 bar to 300.

I think Coltri say that their pump unit are only 70 dB

Of course if you get the jubilee model, you will be the talk of the tow,,,,,, Range.

I have not been able to find much info on it, or even a price, to me so far it lust look like a "look what we can do" product.

TBH i personally feel that large of a battery compressor are a bit silly, i also wonder how many fills you can do on a standard sized dive bottle, or even just a boost from say 200 bar to 300.

I think Coltri say that their pump unit are only 70 dB

Of course if you get the jubilee model, you will be the talk of the tow,,,,,, Range.

Upvote 0

He has concerns about possible loosening of the wheels and legs due to vibration and falling over. The horizontal has solid rubber feet and close to the ground.Patrick, what was Joe’s reasons for picking up a horizontal unit? I’m just curious as most Alkin buyers get the vertical model. There is no price difference between the two.

P

Upvote 0

Can I be Joe's friend too?This was my friend Joe's "pick".

Delivered today. Glad he's my friend

Patrick

View attachment 314293

Upvote 0

these new smaller/portable/gun bottle fill capable compressors have 110v AC as well as 12v DC input, correct?

Found the answer: YES, multi-voltage input. Watching Nate’s video review now

Found the answer: YES, multi-voltage input. Watching Nate’s video review now

Last edited:

Upvote 0

I bought a 'Yong Heng' for 270 bucks. Worked fine for 3 fills, then started to die at 1000 psi. So I got the CS2, and it's been working fine so far. I have two rifles, one 3000 psi and the other 4500, and my son has another 3000 psi rifle. Have aired each up a dozen times without issue.

Penny wise, pound foolish... in this case 27K pennies.

If I continue having good luck with the CS2, I might spring for the CS3. Auto stop, looks like is built better and is overall more convenient. My son can then have the CS2 now that the PCP bug has bitten him!

Penny wise, pound foolish... in this case 27K pennies.

If I continue having good luck with the CS2, I might spring for the CS3. Auto stop, looks like is built better and is overall more convenient. My son can then have the CS2 now that the PCP bug has bitten him!

Upvote 0

Another vote for a Vevor. It's been working well and takes about 5 minutes to go from 120 bar to 230 bar on a 400cc tank. Never comes close to overheating and has the auto stop. I think it was 200 bucks when I purchased it. 110v or 12v makes it portable. https://m.vevor.com/pcp-air-compres...ressor-auto-stop-12v-110v-220v-p_010482656541

Last edited:

Upvote 0

True words you say.

Possible solution.

A 97CF SCBA.

P

Indeed a sensible solution, an even better solution would be multiple SCBA bottles……

Upvote 0

So I have been using a SCUBA tank to keep my 3000 psi Gauntlet running. But now am considering stepping up to a 4500 psi gun, and was hoping to learn more about compressors. What makes the Yong Heng a chore to set up for a single rifle fill?

And are we talking this YH: https://www.amazon.com/Compressor-Auto-Shut-Set-Pressure-Paintball-Separator/dp/B0BLSCHCSG

Or this one: https://www.amazon.com/Pressure-Compressor-30Mpa-Electric-Airgun/dp/B07QP121DC

TIA for recommendations!

And are we talking this YH: https://www.amazon.com/Compressor-Auto-Shut-Set-Pressure-Paintball-Separator/dp/B0BLSCHCSG

Or this one: https://www.amazon.com/Pressure-Compressor-30Mpa-Electric-Airgun/dp/B07QP121DC

TIA for recommendations!

Upvote 0

The bigger compressor is water cooled, and requires a somewhat dedicated regiment to operate it. If you don't follow the regiment by forgetting to turn on the water pump then it will be short lived. It does well topping off large scuba tanks. The small box compressor is portable and fairly strait forward to operate. It is for direct filling of airgun cylinders, and would take quite a while to top off a scuba tank. The key to longevity with either one of those pumps is to keep fresh oil or lube in them and not run them for extended periods of time to where they get hot.iSo I have been using a SCUBA tank to keep my 3000 psi Gauntlet running. But now am considering stepping up to a 4500 psi gun, and was hoping to learn more about compressors. What makes the Yong Heng a chore to set up for a single rifle fill?

And are we talking this YH: https://www.amazon.com/Compressor-Auto-Shut-Set-Pressure-Paintball-Separator/dp/B0BLSCHCSG

Or this one: https://www.amazon.com/Pressure-Compressor-30Mpa-Electric-Airgun/dp/B07QP121DC

TIA for recommendations!

Upvote 0

I have a space in my utility room off my garage where I leave the YH set up next to the normal location of my 45 minute SCBA bottle. The bucket with cooling water with water wetter in it is below on the floor. The bucket is sealed and has a computer radiator on top. The extra moisture filter is above the YH and doesn't move. All I do to refill the bottle is put in the male to male to connect the fill hose of the bottle to the output of the YH, turn on the pump, turn on the fans on the radiator (two flip switches), make sure the vent of the YH is open and turn it on. Then close the vent and the tank starts filling when the compressor pressure is above the bottle pressure (there is a one way valve in the inlet to the extra moisture filter). It took awhile to get this all set up the first time but I have essentially no setup time when I go to use the compressor now.

But if you use an open bucket of water, possibly with ice in it, to cool the second stage you have time to get the bucket full and ready to go. I had to dump the water when I cooled this way because I would get stuff growing in the water if I let it sit there. I refill my bottle about once a month on average. Moving to a closed system with water wetter in the water (an automotive product which helps cooling and also seems to discourage stuff growing in the water) has allowed me to avoid having to change out the water. Some also put a fan on the compressor to assist cooling and that could be another thing to set up.

I've mentioned this before but since a bigger battery powered compressor has come up I will also add that I've used my Milwaukee battery power supply of 15A at 120V to power my YH for a tank fill. It did not come close to exhausting the power supply, I could fill the tank several times before I'd have to recharge it. Knowing I could do this if I ever need to was worth trying it but the Milwaukee power supply weighs about 50 lbs so I don't see dragging it with the YH and the cooling setup around to be very practical. But if I ever need to, I could. If I go to shoot away from home I just take my SCBA tank.

But if you use an open bucket of water, possibly with ice in it, to cool the second stage you have time to get the bucket full and ready to go. I had to dump the water when I cooled this way because I would get stuff growing in the water if I let it sit there. I refill my bottle about once a month on average. Moving to a closed system with water wetter in the water (an automotive product which helps cooling and also seems to discourage stuff growing in the water) has allowed me to avoid having to change out the water. Some also put a fan on the compressor to assist cooling and that could be another thing to set up.

I've mentioned this before but since a bigger battery powered compressor has come up I will also add that I've used my Milwaukee battery power supply of 15A at 120V to power my YH for a tank fill. It did not come close to exhausting the power supply, I could fill the tank several times before I'd have to recharge it. Knowing I could do this if I ever need to was worth trying it but the Milwaukee power supply weighs about 50 lbs so I don't see dragging it with the YH and the cooling setup around to be very practical. But if I ever need to, I could. If I go to shoot away from home I just take my SCBA tank.

Upvote 0

Think you are correct. They are all basically the same destined to fail at some point units with a different case on them.

Upvote 0

That sounds like an awesome setup, and you seem to be doing it right. Instead of water wetter, why not propylene glycol? As in boiler antifreeze? Water wetter is just a surfactant. AF has anti-corrosion properties. And I would think it would prevent bacterial growth, but cannot swear to it, as I have only used it in closed systems.I have a space in my utility room off my garage where I leave the YH set up next to the normal location of my 45 minute SCBA bottle. The bucket with cooling water with water wetter in it is below on the floor. The bucket is sealed and has a computer radiator on top. The extra moisture filter is above the YH and doesn't move. All I do to refill the bottle is put in the male to male to connect the fill hose of the bottle to the output of the YH, turn on the pump, turn on the fans on the radiator (two flip switches), make sure the vent of the YH is open and turn it on. Then close the vent and the tank starts filling when the compressor pressure is above the bottle pressure (there is a one way valve in the inlet to the extra moisture filter). It took awhile to get this all set up the first time but I have essentially no setup time when I go to use the compressor now.

But if you use an open bucket of water, possibly with ice in it, to cool the second stage you have time to get the bucket full and ready to go. I had to dump the water when I cooled this way because I would get stuff growing in the water if I let it sit there. I refill my bottle about once a month on average. Moving to a closed system with water wetter in the water (an automotive product which helps cooling and also seems to discourage stuff growing in the water) has allowed me to avoid having to change out the water. Some also put a fan on the compressor to assist cooling and that could be another thing to set up.

I've mentioned this before but since a bigger battery powered compressor has come up I will also add that I've used my Milwaukee battery power supply of 15A at 120V to power my YH for a tank fill. It did not come close to exhausting the power supply, I could fill the tank several times before I'd have to recharge it. Knowing I could do this if I ever need to was worth trying it but the Milwaukee power supply weighs about 50 lbs so I don't see dragging it with the YH and the cooling setup around to be very practical. But if I ever need to, I could. If I go to shoot away from home I just take my SCBA tank.

I don't have the luxury of space, so while your YH setup is one I'd gladly model, I guess a smaller, direct-fill for my rifles is what I'll go with. Sounds like the GX CS4 with the upgraded motor for my occasional use. Will this require an additional/external moisture filter?

Thanks for the quick answer and excellent descriptions!

Last edited:

Upvote 0

I use about three gallons of Peak lifetime premixed antifreeze in a covered tote as a reservoir with the water pump inside of it. No algae, only minor evaporation, and no build up of salts or corrosion in the compressor head passages in the couple of years that it has been set up there now. Good antifreeze is made for automotive applications with various types of metal and plastic components.That sounds like an awesome setup, and you seem to be doing it right. Instead of water wetter, why not propylene glycol? As in boiler antifreeze? Water wetter is just a surfactant. AF has anti-corrosion properties. And I would think it would prevent bacterial growth, but cannot swear to it, as I have only used it in closed systems.

I don't have the luxury of space, so while your YH setup is one I'd gladly model, I guess a smaller, direct-fill for my rifles is what I'll go with. Sounds like the GX CS4 with the upgraded motor for my occasional use. Will this require an additional/external moisture filter?

Thanks for the quick answer and excellent descriptions!

I have some WatterWetter and though these compressor heads don't get boiling hot, it wouldn't hurt for a couple of ounces to be added for even better cooling efficiency. But then again, maybe this product is what is allowing algae growth (posted by JimD) and I shouldn't try to fix what isn't broken. For the ten minutes of run time my compressor does to top off a tank, the coolant gets barely warm to the touch.

Last edited:

Upvote 0

Pure Peak, or mixed with water?I use about three gallons of Peak lifetime premixed antifreeze in a covered tote as a reservoir with the water pump inside of it. No algae, only minor evaporation, and no build up of salts or corrosion in the compressor head passages in the couple of years that it has been set up there now. Good antifreeze is made for automotive applications with various types of metal and plastic components.

I have some WatterWetter and though these compressor heads don't get boiling hot, it wouldn't hurt for a couple of ounces to be added for even better cooling efficiency. But then again, maybe this product is what is allowing algae growth (posted by JimD) and I shouldn't try to fix what isn't broken. For the ten minutes of run time my compressor does to top off a tank, the coolant gets barely warm to the touch.

EG is much more toxic than PG (food-safe). Since we're not using our compressors around food, that's not really relevant. (Becomes relevant when dealing with changing the fluid, obviously)

While a 50/50 mix will get around the best anti freeze properties for water, and considering that AF isn't as efficient at transferring heat when used full strength as is water, or a 50/50 mix, I guess it boils down to (SWIDT?)... how hot does the water get when pumping? Water cools the best, but is susceptible to microbes. Glycol alone cools less efficiently. But is superior heat transfer the most desirable trait, or is preventing water contamination? If the latter, I'd say pure glycol (either EG or PG) would fit the bill. Not knowing how warm or hot the reservoir gets during a SCBA tank fill, I don't have the ability to make other than a guess.

Upvote 0